Episodes

Episode 42

The Heart of HX50 Production

6m

14 Jan 2025

Production Centre 1 marks a monumental milestone in our journey to revolutionise helicopter production. 🚁

Episode 41

Designing HX50's Lighting

3m

23 Sep 2024

Join us as we delve into the meticulous design process behind the HX50's lighting system, aimed at exceeding legal requirements to enhance safety and the flying experience.

Episode 40

FADEC Technology

2m

15 May 2024

FADEC technology promises unprecedented fuel efficiency and optimal performance, turning aviation dreams into reality. Join us as we unveil the future of flight control, where precision and economy meet in perfect balance.

Episode 39

Welcome to Production Centre One

4m

2 Apr 2024

Join us as we transform this vast space into a state-of-the-art production facility, ready to support the final stages of our helicopter development programme.

Episode 38

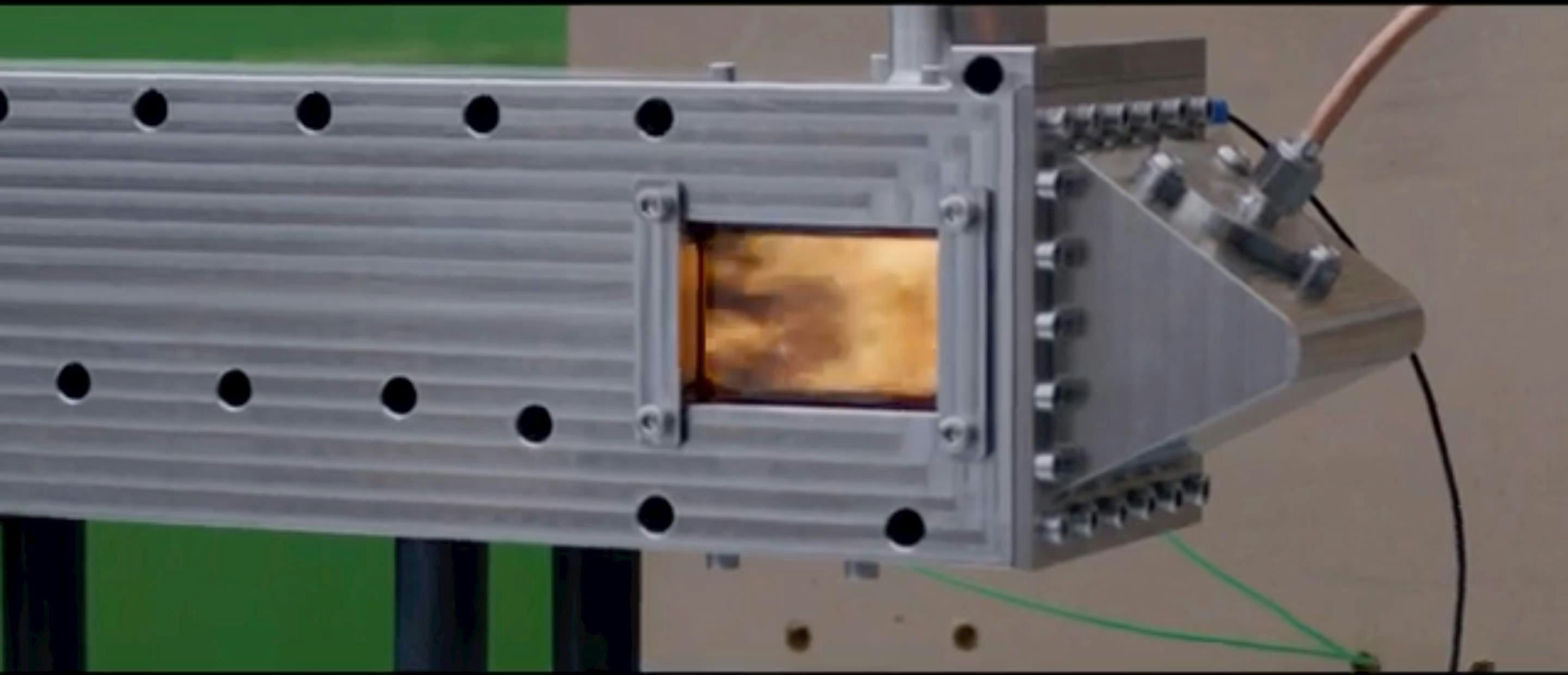

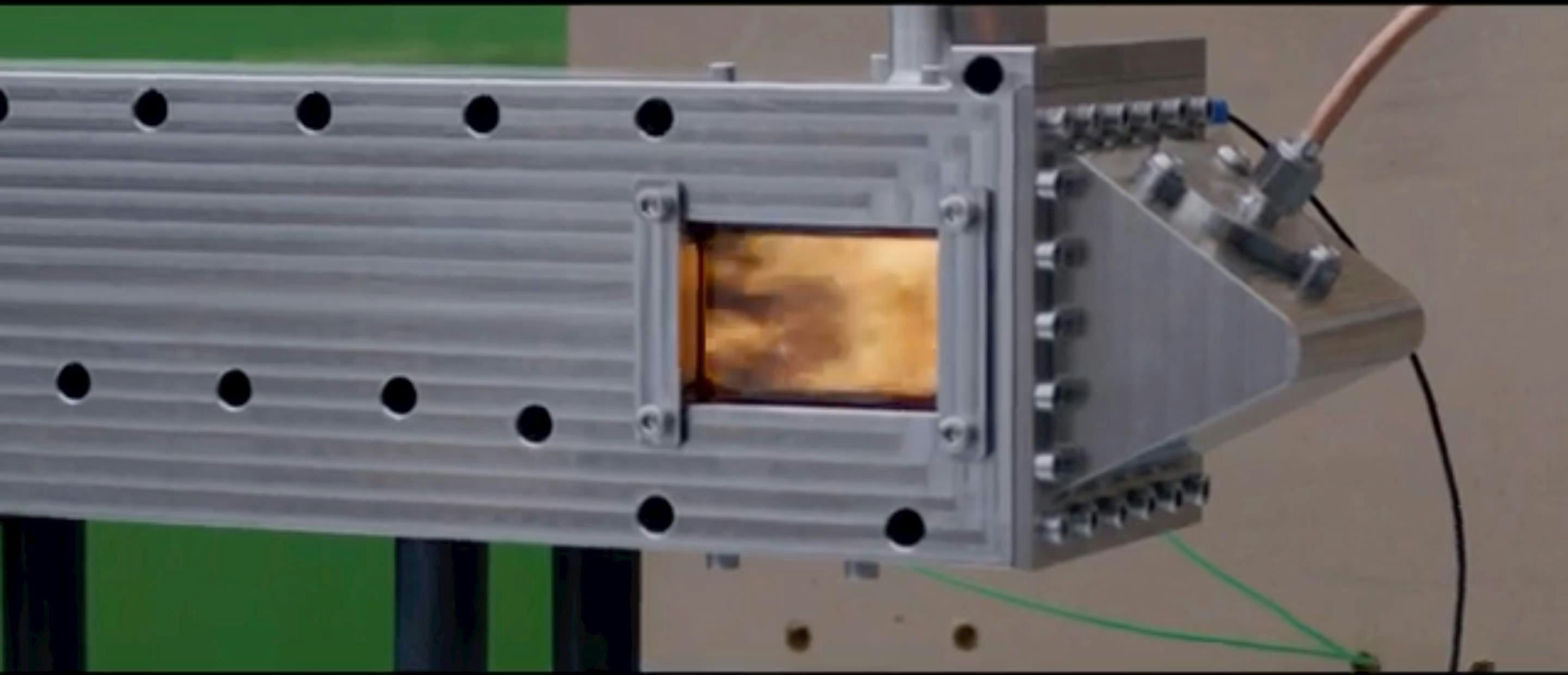

GT50's First Flames of Success

2m

25 Feb 2024

In an exhilarating breakthrough for the GT50 project, the engineering team celebrated the inaugural ignition of the GT50, marking a pivotal moment in its development

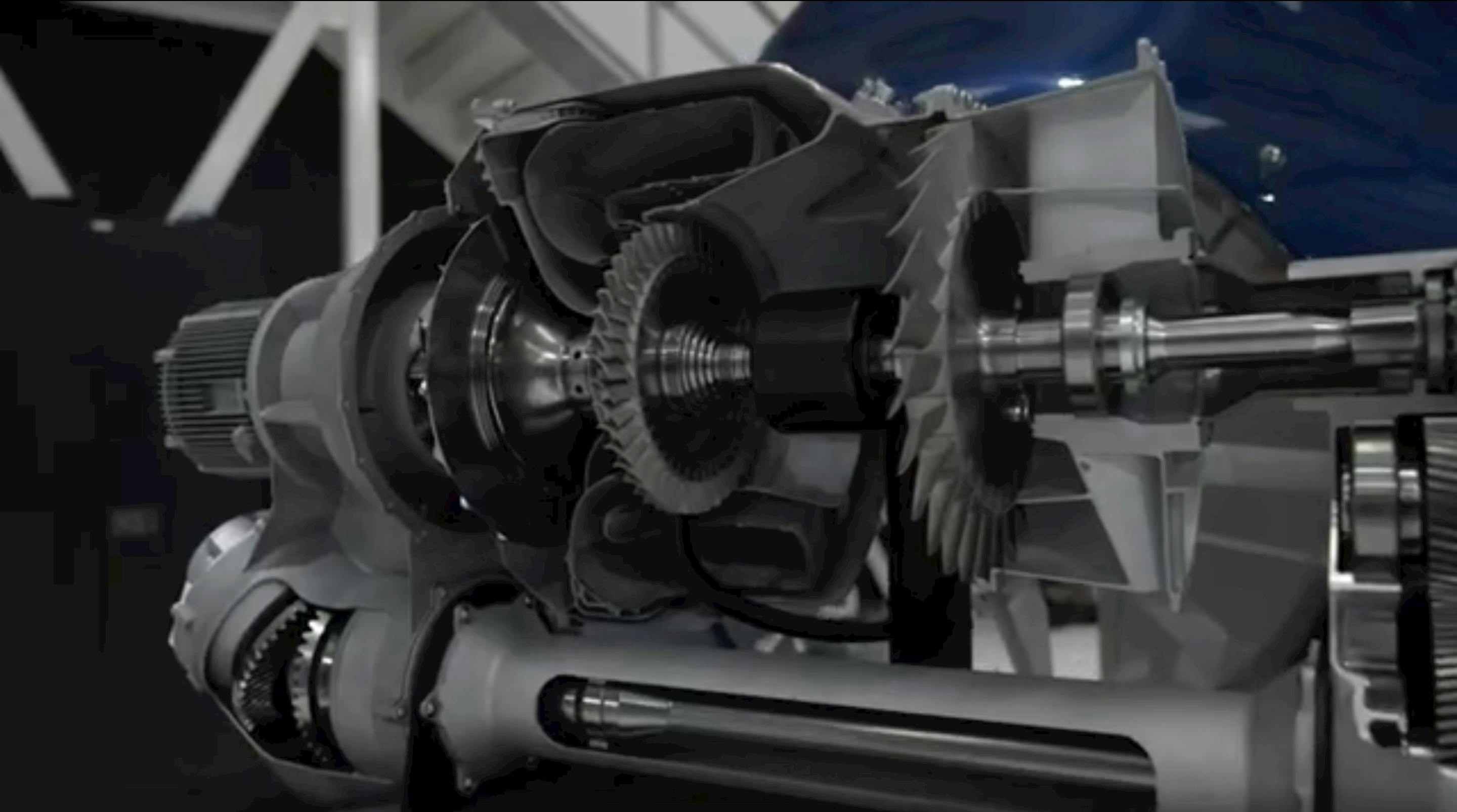

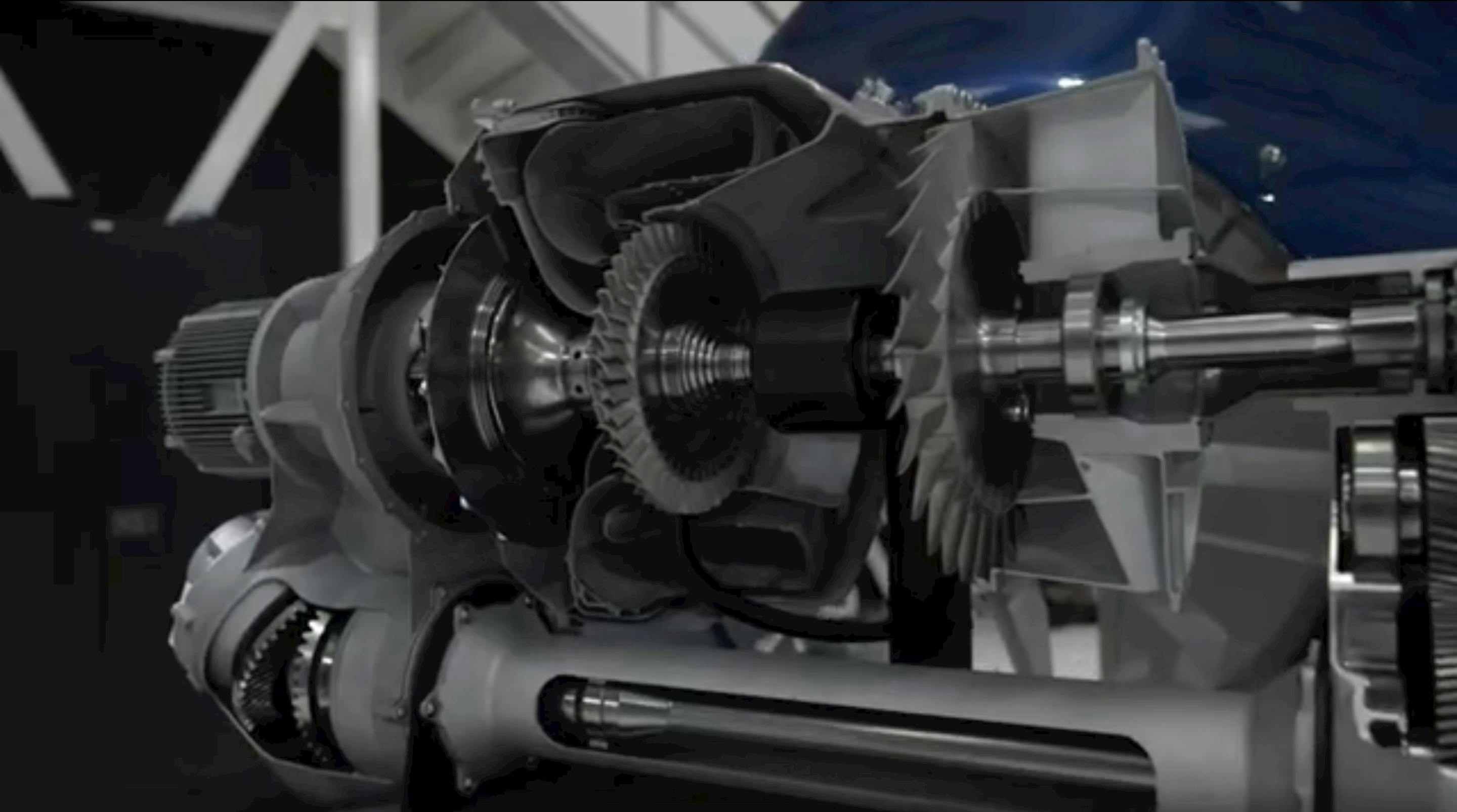

Episode 37

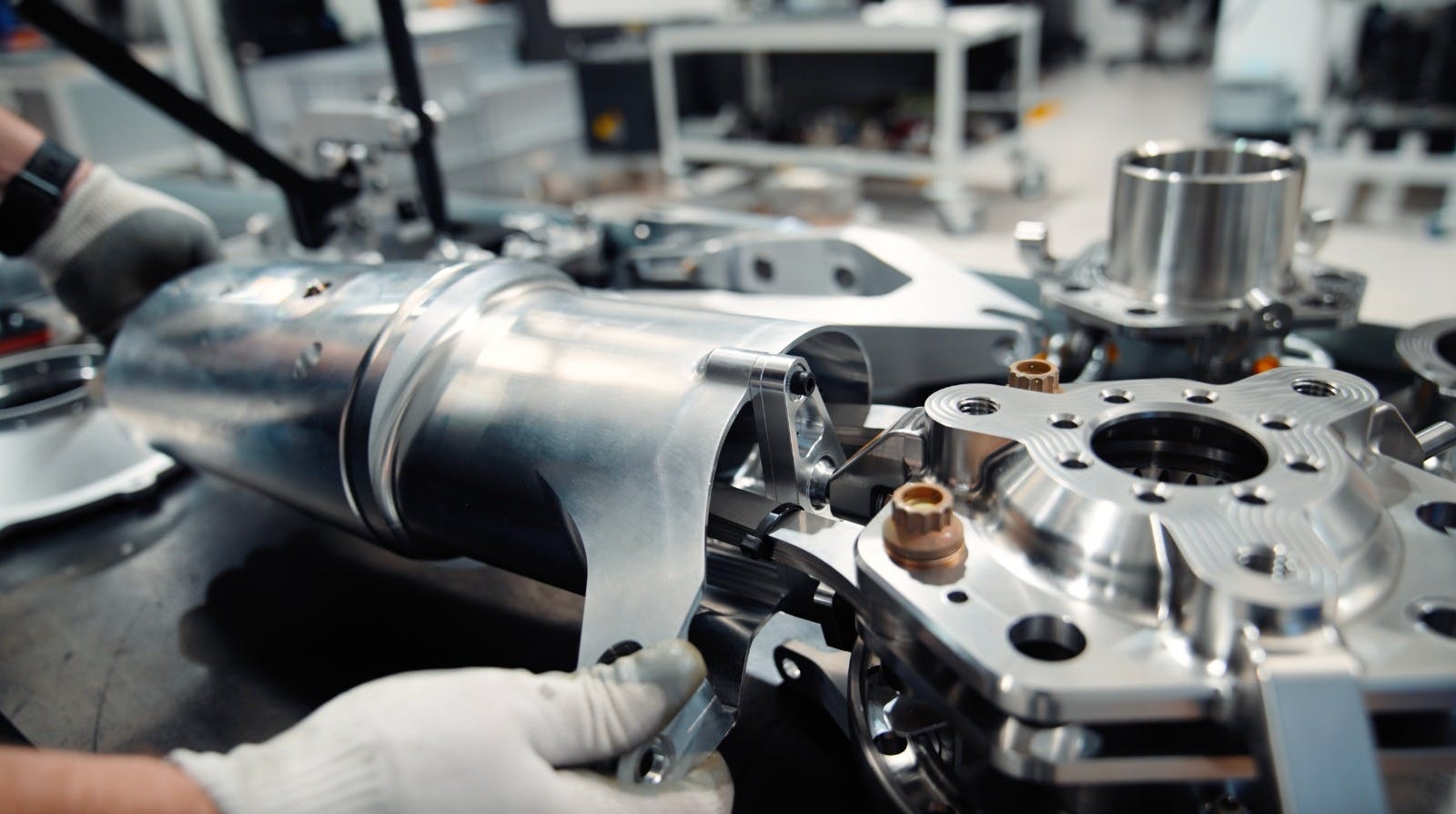

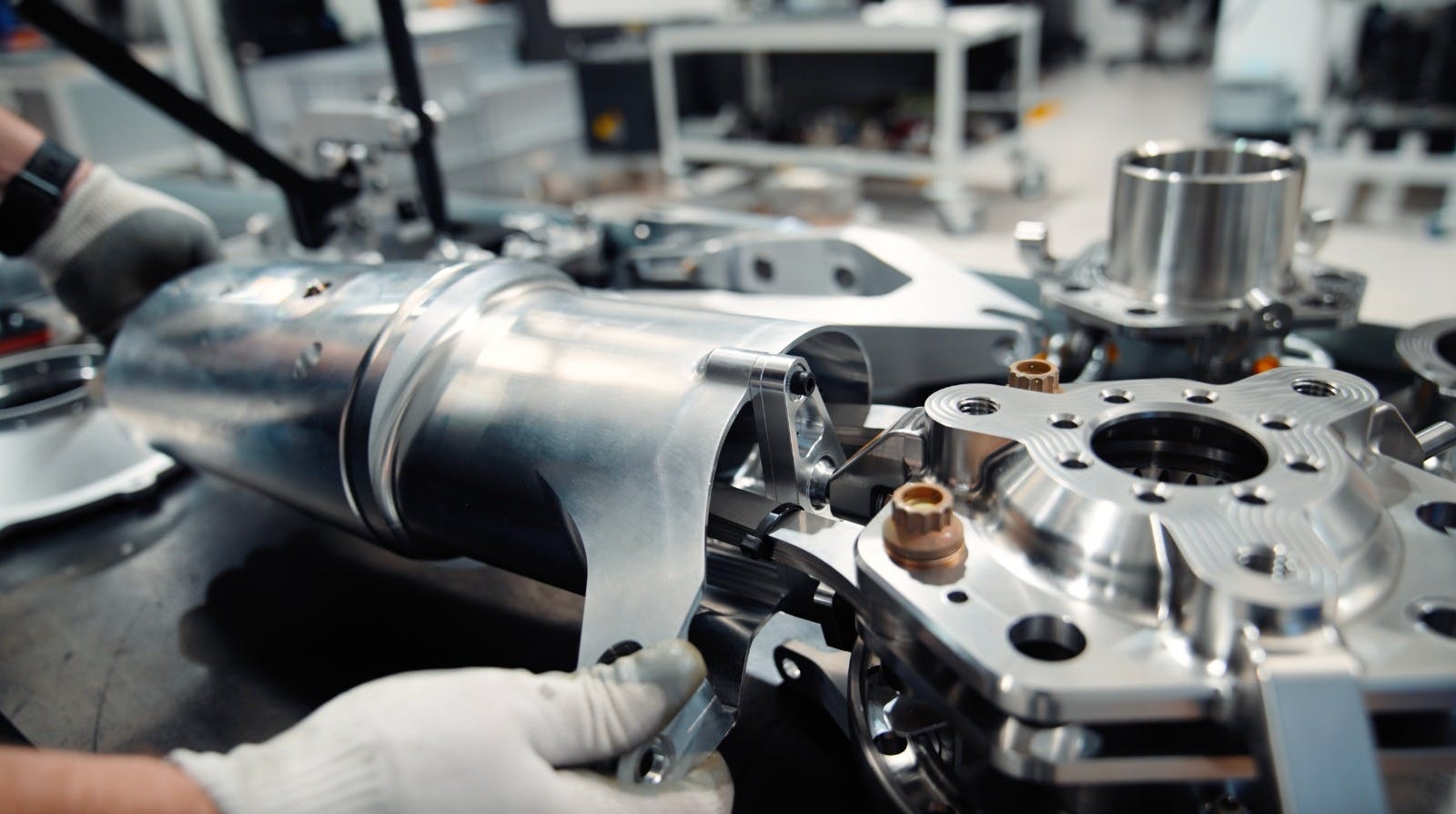

Inside the Creation of the GT50 Engine

3m

22 Feb 2024

Dive into the groundbreaking journey of the GT50 engine, the powerhouse behind the HX50 helicopter, designed to redefine aviation standards.

Episode 36

Defying the Odds

5m

15 Feb 2024

We delve into the challenging yet exhilarating process of building two HX50, set against a tight deadline.

Episode 34

Building the Main Rotor System

6m

10 Nov 2023

In this episode, we explore the detailed assembly of the HX50's main rotor system and learn how its design prioritises the needs of inexperienced pilots without compromising on safety, with an emphasis on high inertia for emergency manoeuvrability and low drag for efficient flight.

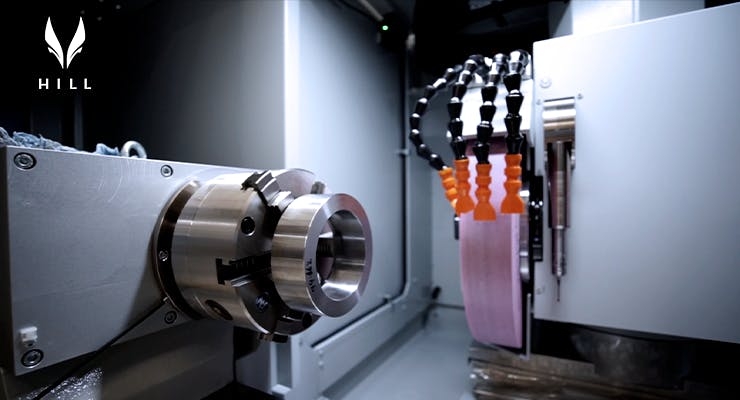

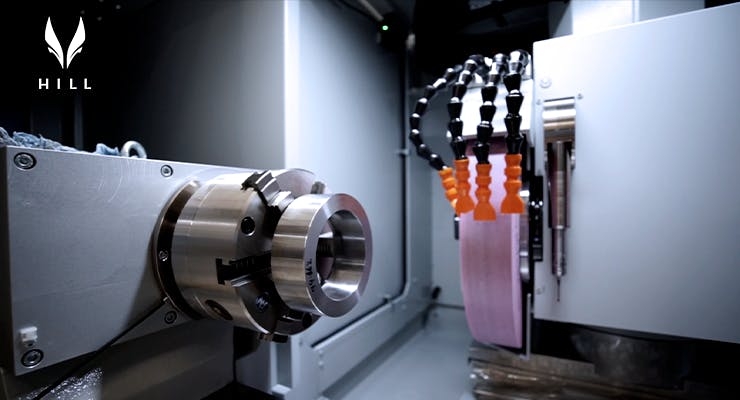

Episode 35

Revolutionising Gear Production

6m

10 Nov 2023

Dive deep into the complex world of gear production with our latest episode. Explore the intricate, multi-step process of manufacturing gears, highlighting the immense time and effort required to bring these essential components from concept to completion.

Episode 33

Casting vs. Machining

5m

20 Oct 2023

In the world of helicopter manufacturing, precision and efficiency are key to success. But which manufacturing process reigns supreme: casting or machining?

Episode 32

Inside the HX50 Power System

5m

5 Sep 2023

Dive into the world of the HX50 power electronics and discover how they efficiently convert, control, and condition electrical power for various systems. Get an exclusive look at the integrated Motor Generator Unit (MGU) and Power Management Unit (PMU), showcasing our commitment to vertical integration and cutting-edge technology.

Episode 31

Building HX50's Strength

7m

11 Aug 2023

In this episode, we take a look at the innovative methods that are being used to make the HX50's carbon fiber framework incredibly strong and resistant to vibrations. We discuss the challenges of creating a tailboom that is both strong and lightweight, and we show how honeycomb material is being used to achieve this.

Episode 30

HX50 Doors - Where Ergonomics Meet Luxury

4m

29 Jun 2023

Discover the intricate details that go into designing the doors of an HX50 helicopter. Learn how carbon fiber construction and design innovations contribute to a more luxurious and satisfying experience.

Episode 29

Unveiling the tailboom

4m

9 Jun 2023

Get a glimpse of airframe number five and tailboom number one, showcasing the latest developments of the stunning HX50. With intentional design features, like the sacrificial piece under the tail fin, this nearly 10-meter long helicopter is changing the game in the general aviation market.

Episode 28

Unboxing Our New Hexagon Leitz CMM Machine

6m

14 Apr 2023

Join us as we as we unveil our latest acquisition - the Hexagon Leitz machine for ultra-precision measuring. In this video, we'll take you through the key features of this cutting-edge machine and why it's essential for measuring gears and other components with optimal functionality.

Episode 27

Heat Treating and Shot Peening for Durable Gears

6m

28 Mar 2023

Follow Mark and Jason as they visit companies and review the equipment to ensure that their gears are made using the best manufacturing processes available.

Episode 26

Airframe 4 - The next big stage in development

4m

3 Mar 2023

An exciting update on Hill Helicopters' latest development: Airframe 4. In this video, we get an inside look at the new airframe and learn about the advancements being made in foam and surface application.

Episode 25

Carbon fibre revolutionises light helicopter design

4m

23 Feb 2023

Find out why Hill chose this route and how it has been so successful while at the same time proving cost effective. It’s all about striving for the ultimate in streamlining, speed, payload, hover performance and of course safety.

Episode 24

Achieving perfection on the HX50 main rotor gearbox

4m

16 Feb 2023

Find out about the technicalities of making aerospace parts and how the engineering team at Hill are maximising the efficiency of gears being made for the HX50, with close-up footage and extensive explanation of the entire process.

Episode 23

Our third airframe revealed

4m

10 Feb 2023

Hill perfects its infusion method to turn out its most successful airframe yet, inspiring confidence and enthusiasm from the whole team.

Episode 22

It’s all in the details

5m

20 Jan 2023

We get a tour of DC2 and an idea of the incredible amount of effort that is going in to perfect the airframe. A lot has been learned by producing two airframes and this is informing the third version, as the edges and surfaces get smoother and tiny imperfections are eliminated.

Episode 21

Vertical Integration and the HX50

6m

11 Jan 2023

Learn about the history behind the decision Hill made to manufacture all of its components in house, and how this system benefits owners with their initial purchase, as well as over the long term.

Episode 20

The first prototype airframe emerges in DC2

6m

3 Jan 2023

Hill have been able to demonstrate that their approach to making a monolarge in a single piece not only works, but is remarkably cost-effective. Watch how it’s done, from start to finish.

Episode 19

HX50 on track with chasing microns and hitting tolerances

6m

23 Nov 2022

The news is good for in-house manufacturing of the HX50’s main rotor gear box: find out about the demanding measurements being done on tolerances on our gears, and why it’s so important.

Episode 18

Industrial Metamorphosis: from tools to moulds to monolarge

7m

4 Nov 2022

The whole process is demonstrated and explained in detail, with the chance to see the amazing result, inside and out – a fully assembled full-scale HX50 monolarge.

Episode 17

How gears are tested for precision

5m

17 Oct 2022

A detailed demonstration of how the HX50’s main rotor gearbox gears are being tested by a company that specialises in this technology, with lots more interesting information on gears in general.

Episode 16

Manufacturing components for the GT50 engine

5m

29 Sep 2022

Jason and Mark go on an expedition to look at a very sophisticated machine that will drill thousands of tiny precision holes in fabricated sheet metal components - you can follow along as the meeting, consultation and demonstration unfold.

Episode 15

New CMM installed at Hill Headquarters

8m

26 Jul 2022

Hill enter a new stage in production of the HX50 where their CMM testing facility is being set up to test components they are manufacturing as part of their vertical integration strategy. All this is demonstrated in detail by Jason Hill.

Episode 14

High performance engine demands high grade materials

8m

14 Jul 2022

Becoming an organisation that’s able to produce really highly technological parts is a massive journey in its own right, quite apart from designing and developing the revolutionary HX50 helicopter. Hill is approaching both with aplomb.

Episode 13

Hill expands its workspace

6m

9 Jun 2022

DC2 revolves around everything related to composites and is the future setting for the manufacture of the HX50 fuselage. Then there’s DC3 – an area devoted to the GT50 engine, while DC1 will concentrate on precision engineering. Prepare for a great guided tour!

Episode 12

The complex process of gear-making

7m

11 May 2022

Jason gives us a clear, comprehensive explanation of what turns a piece of high grade alloy steel into a gear that will withstand the colossal stresses it will be subjected to during its life in service in the GT50 engine.

Episode 11

Testing torque values for Helimove

5m

23 Mar 2022

An impressive demonstration of what the Helimove option will be able to do, accompanied by an explanation by mechanical design engineer Gareth on the importance of establishing what the actual torque values will be in practice.

Episode 10

Visit to Cranfield Impact Centre

5m

10 Mar 2022

Tim Gulland, Lead Composites Engineer sets the scene for tests for the seat attenuator with an impressive live demonstration. See how technology first developed for Formula 1 is being adapted to make the HX50 seats not just comfortable but extremely safe.

Episode 9

1/3 scale model of HX50

10m

27 Dec 2021

The fusion experts at Composite Integration have been working hard to produce a one third scale model of the HX50. They explain what a huge challenge this was, and Jason Hill tells us why composites are so crucial to the project.

Episode 8

CNC machines installed and ready to go

8m

23 Nov 2021

An exciting new chapter in the HX50 development programme takes off as huge 5-axis and 3-axis CNC machines are installed and commissioned.

Episode 7

Materials testing up close

5m

20 Oct 2021

The progression that begins with developing the architecture for the structure of the aircraft, followed by a rigorous testing regime to determine the core material properties that any given part will deliver in practice.

Episode 6

Why build a 1/3 scale model HX50?

5m

4 Oct 2021

An important stage in the HX50 journey is revealed on a visit to the Datum factory where engineers are turning Hill’s design for the fuselage into a one third scale 3D model in preparation for testing.

Episode 5

Making gears for the HX50

5m

20 Aug 2021

Jason Hill gives us a fascinating look at how gears are being manufactured for the HX50 engine, while explaining the rationale behind choosing the method being used, and how it fits with the price point that has been achieved.

Episode 4

Composites and the challenges

8m

12 Aug 2021

Jason Hill visits a composites factory to collaborate with the experts on how to solve the trickier aspects of resin infusion composite manufacturing, needed for the one-piece fuselage that has been designed for the HX50.

Episode 3

In Conversation with Steve Brooks

6m

25 Jun 2021

Join helicopter pilot, engineer and intrepid explorer Steve Brooks in a lively discussion about his record-breaking travels along with reflections on the HX50 and its positive implications for the aviation industry.

Episode 2

In Conversation with Peter Wilson

10m

17 Jun 2021

Peter Wilson, known for his 3 major expeditions around the world by helicopter, joins Sam to talk about the aviation industry and the positive changes the HX50 is bringing to it.

Episode 1

Meet the protagonists

6m

6 May 2021

Filmmaker Sam meets up with Jason Hill for a site visit at a rubber moulding company where components are being custom made for the HX50.

JOIN OUR GROUP PRESENTATION

Are you interested in the HX50? Book your spot in our group presentation and learn why the HX50 will be better than your current helicopter.

What's in the presentation

Who

Mischa Gelb (aka Pilot Yellow) and Ruben Dias

What

Exclusive full details about the HX50 not yet available to the public

How

30 minutes presentation + Q&A

Be part of the journey

Get all the relevant news and updates about the HX50 delivered to your inbox.

HX50

Exterior Concept

Interior Concept

GT50 Turbine Engine

General Aviation 2.0

Hill Digital Cockpit

News & Stories

Technical Details

Range Simulator

Journey to HX50

ADDRESS

Hill Helicopters

Unit 3, Shackleton Way

Stafford, ST16 1GY

United Kingdom

Contact

General Enquiries:

+44 (0) 1384 590700

Accounts:

+44 (0) 1384 590700

Sales:

+44 (0) 1889 228040

hello@hillhelicopters.com

ADDRESS

Hill Helicopters

Unit 3, Shackleton Way

Stafford, ST16 1GY

United Kingdom

© 2026 HILL HELICOPTERS