RECAP March's HX50 MONTHLY UPDATE & AMA

Our biggest news this time is the successful showcasing of HX50 in December at two big events at Duxford Air Museum, followed by its unveiling to the commercial market at HAI Heli Expo 2024 in Anaheim, California in February.

Response from our customer base, friends and visitors seeing it for the first time, and then the broader market, shows that HX50 is resonating with the market in the way we always hoped it would. - Jason

17 Apr 2024

And it helps to validate Hill’s vertical integration strategy, along with the whole premise of GA 2.0 - not only were we able to show that we can manufacture all the key elements we need to and bring the attributes and the price point together at a very accelerated timescale, but we also demonstrated that if you make an aircraft that people want, general aviation can thrive again.

Of course, many of our customers and supporters have been on the HX50 journey since it started, but it was gratifying to receive such an incredible welcome from the commercial market. Not surprisingly, sales remain buoyant, with a total of 1,283 aircraft sold, 913 HX50s and 370 HC50s in 70 countries.

GVTOL

There was also a positive response to the announcement of our GVTOL strategy, which promises a sustainable future for general aviation, not just environmentally but importantly, economically, making GA pay for commercial operators, as well as our core private ownership.

The main pillars of GVTOL are:

1. The GT50 engine is designed to run on sustainable aviation fuel as well as conventional jet fuel.

2. Hill’s vertically integrated supply chain allows us to control costs from end to end.

3. The Hill insurance program will give private and commercial operators alike access to cost effective insurance.

4. Hill support centres and support partners will offer customers world class, worldwide support for their aircraft.

5. Accessible aircraft finance will eventually open GA to the broader market.

New headquarters

Within the next 2 months we will be moving into a larger rented facility that will put all the activities now taking place in the three current development centres under one roof, Production Centre 1. This means we can complete the development process and gradually develop out the production infrastructure we need, expanding that space in a cellular manner to increase the capacity to where we need it to be in line with the targeted production date, in a cost-effective way.

We had reached the point that the huge, new (15m by 14m) gantry mill needed for production would have taken up over 80% of the available floor space that was left at DC1. Having moved to a dual site approach, we will be able to carry out flight ops using permitted development rules at a separate location, allowing production to go ahead in our new headquarters.

One of the most important things in being able to rapidly execute a development project is getting the culture right within your organisation – Jason

What will go into what is now the enormous shell of a brand-new building is the huge new gantry mill, along with an air-conditioned machine shop for the precision production of gears, bearings, turbine components, servo actuators, etc. There will be a complete composites production line, plus paint shop, trim, wiring & build stations, electrical shop, avionics and electrical laboratory facilities.

In addition, we’ll have a customer showroom, a customer lounge, a canteen, and then a complete office suite on the mezzanine layer, with space for engineering and operations staff, and a production control office which gives complete visibility of production activities on the factory floor.

One of the big advantages of the new facility is its expansive yard area that provides storage facilities as well as a space to conduct outdoor testing. All this plus loading bays needed to facilitate the flow of materials in and out of the factory.

Other priorities, in preparation for the first GT50 run and PP1 build and first flight later this year, include growing our team. We have recently been joined by our new CEO, Peter Teare, who is helping run the commercial aspects of the business, leaving Jason to focus more on driving the technical side.

GT50 engine

Intensive work on the GT50 engine continues, with more and more elements undergoing or nearing the testing stage, some results actually surpassing our expectations.

During the GT50 engine development program we had an opportunity to take 9 kg out of the engine by removing the bevel gearbox at the front of the engine.

To do this we had to modify the way the engine sits in the fuselage. We’ve now modified the engine installation. The drivetrain has been largely updated and we’re now developing out an updated firewall solution to provide the fire containment we need around the engine for this updated configuration.

Compressor and combustor manufacture

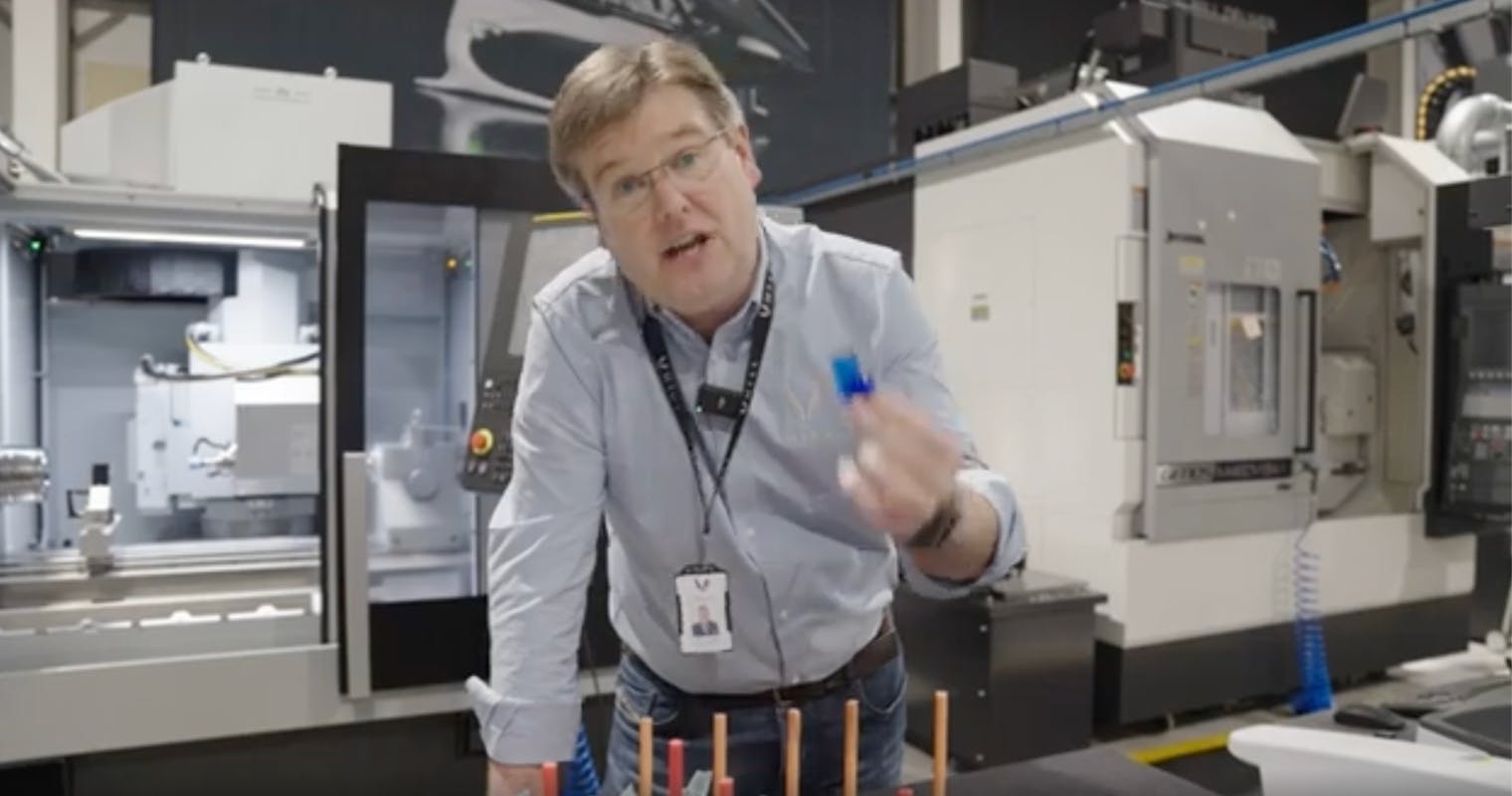

We are currently manufacturing the GT50 test compressor, the one that will actually run in the gas generator and the power turbine tests that are going to take place later this year. This involves all the treatments, inspections, balancing of the wheels and then managing the clearances between the impeller tip and the stationary components. Over the next week or two we’ll be producing the first GT50 impeller to run in a test engine.

Blade and casing casting

To productionise the GT50 we now have to extend the already successful turbine blade casting process that resulted in good quality turbine blades that passed NDT inspections, to casings.

Blade root grinding

Through a multiple operation process, once we’ve ground the root and the wedges and the tips of the blades, then we’ve got a production grade aerospace turbine blade, all made in house by us through this palette of processes. We are about to start grinding the very first tree roots on Hill turbine blades.

Gas generator turbine disc testing

We’ve got the very first GT50 gas generator turbine disc in production right now, which will run in the test engine over the coming months. We’ve developed all of the CMM (coordinate measuring machine) and the non-destructive test processes (NDT) to be able to qualify that the disc has the necessary integrity and quality.

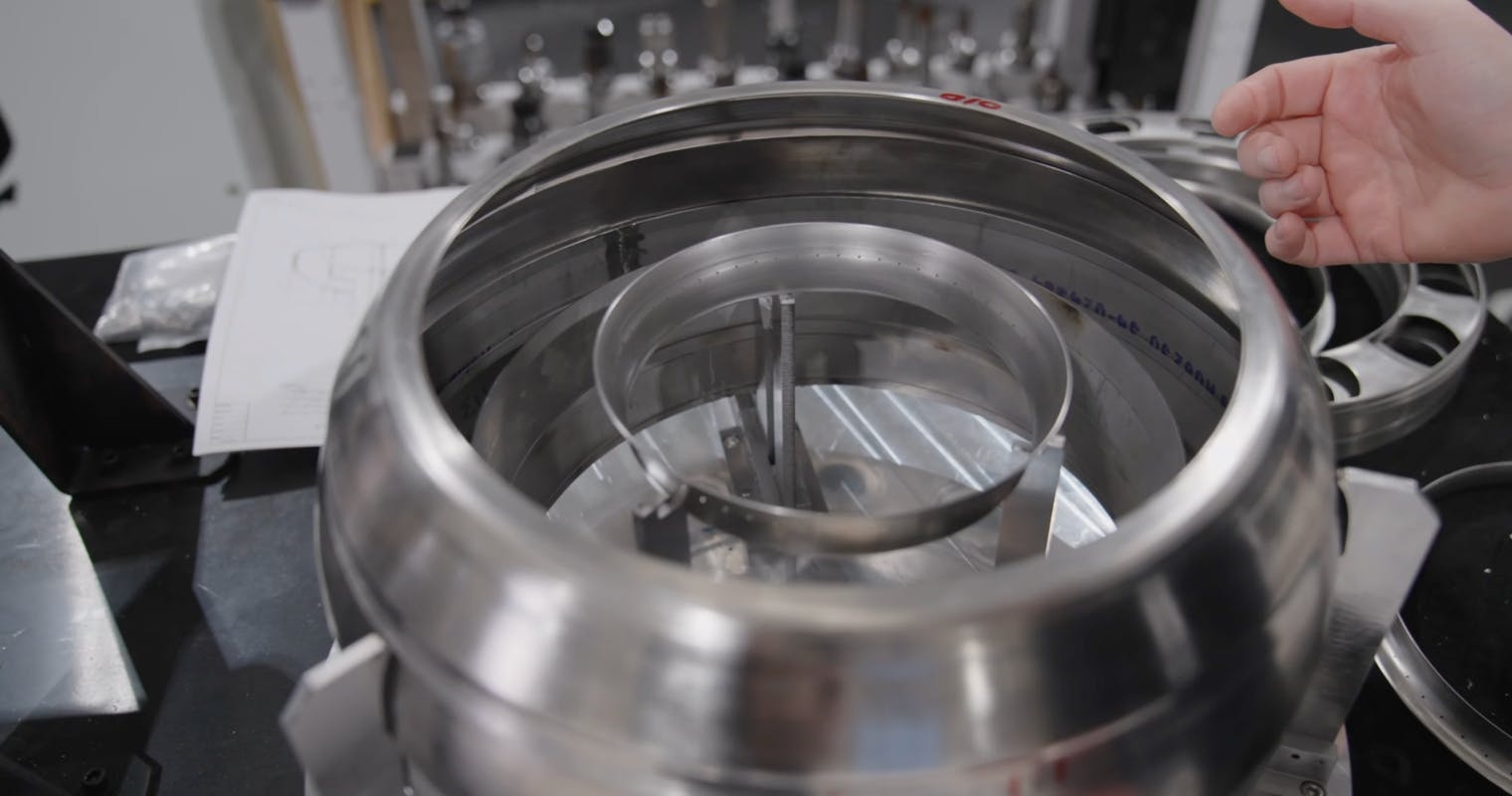

Annular combustor

We’ve also been working extensively on the production of the annular combustor, critical to make a compact, lightweight engine. The GT50 test combustor is in production, with all of the rolled parts now successfully manufactured. We’re just finishing the very last press tool for the components that can’t be rolled or spun and then we’re then left with the assembly and the welding, ready for the combustion test rig.

Starter generator

The GT50 prototype starter generator is also in production. The PMU or motor control unit has also been developed. All of the algorithms necessary to control the high frequency, high voltage AC electric that’s generated in 3 phases has been developed. We’ve also got the algorithms to drive the starter generator as a motor and we’ve been carrying out passive load testing on those algorithms using the electrical test bench.

The devices being built are expected to be ready about mid-April. We’re now in a position where the MGU, the starter generator hardware, is imminent. The control systems have been developed and the test rig is being shipped to us. By mid-April we should have both the GT50 starter generator and also the test bench to fully develop and qualify it.

FADEC

The GT50 FADEC system development board, the very first physical embodiment of our FADEC system, has now been built and delivered. The FADEC control laws have been developed and are now sitting on the FADEC board waiting to be tested with a model in the loop, and then later with hardware in the loop. It is just waiting for a gas generator to control, on the combustion test rig.

Combustion test rig and casing

The combustion test rig has been fired up for the first time, and the preliminary results we had were fantastic - a lot of the key parameters that we needed to see working in this first run worked beautifully. We can hold the flame stable; we can ignite reliably, and now we have to tune the fuel injection and the air blast atomiser to get that shape burning, get the chemistry of the combustion right and get that process working properly.

We’ve already learned a lot from this rig. In the next few weeks, we’ll have the fuel nozzles sorted, and the air blast atomisers, and that then freezes up ready to run in the full annular combustor and tested.

In preparation for the compressor, the turbine blades, and the turbine discs all coming together, we also need to ensure that the static components of the engine are ready for the gas generator test. We’re taking the same suite of processes we’ve developed for the blades and casting these sorts of enclosures to give us that low-cost production solution for really high integrity parts for the engine.

The very first GT50 combustion casing passed (with a healthy margin) a hydrostatic test to ensure that it can withhold all of the pressures it’s going to see in service.

Drivetrain

We are now acing the manufacture of verified, aerospace quality gears, with results in international standard spur gear test fatigue articles well above anticipation marks. Formal reports are back on all aspects of that testing and our permissibles for design stresses and cycles are even better than we expected.

Every element of that process, the case depth of the hardened material, the hardness of the case itself, the fatigue parameters, the tensile strength, the spread of variability, is absolutely spot on. We can now proceed with confidence to drivetrain optimisation and then full testing of the HX50 drivetrain.

Digital cockpit

Features now being rolled out for the latest version of the digital cockpit include the startup page, how you initially interact with the digi cockpit, how you manage the engine start process, and how all that is linked together with both the app and everything else. Other UI/UX enhancements include developing out the way the navigation routes from your electronic flight book are synchronised with the flight control computer on the aircraft, and how that’s communicated via the digi cockpit to the pilot.

We’ll shortly be reaching out to some experimental test pilots on the technical side and also a few people from within the pilot community, our customer community, to come and do some structured tests for various use cases for the digi cockpit.

Airframe

Cabin seats

The HX50s cabin seats must be exceptional, worthy of the world’s first aerial grand tourer. Over the last couple of months, we’ve gone back to basics from a comfort point of view, still carrying forward all of the crashworthy stuff, all the production technologies, making sure that things like the seat back angle, the seat tray angle, and the subjective nature of the depth and stiffness of the foams we use, when combined with the trim materials, is just right to give the best possible feel to the widest range of our customers as we possibly can.

We’ve completed a range of simple comfort tests and combined the really well known ergonomic fundamentals with the subjective feel that you simply can’t get away from. It always comes down to a subjective view of a test panel to get that seat comfort just right. – Jason

Fire test cell

We are developing our fire test cell for the firewall, trading off two versions of a firewall system for HX50 that will be tested to prevent the effects of an engine or other system fire within the aircraft.

We have to get the ride and the vibration and the handling qualities to the right level for the very first aerial grand tourer. – Jason

Now that the mechanical systems are mature we have to make sure we get the vibration right on the aircraft. We do this by getting the kinematics of the way we mount the gearbox done properly. We have to ensure the kinematics of the pylon is focused at the right point so the in-plane loads that are generated at the rotor don’t get transferred to the mounting. We then need some anti-resonant mountings for the gearbox to take out the vertical hop. We still have room for various types of vibration absorber within the doughnut on top of the rotor system. All of that work is being captured now that we’ve got the finished configuration of the mechanical drivetrain.

Electrical Systems

We are conducting landing light trials to achieve enhanced safety at night. The wingtip landing light systems give you a broader spread of illumination of the ground, and then the nose landing light gives you a dual focus to help you identify landing sites under normal approach conditions and emergency conditions.

Having harnessed the best of modern LED technology, our tests will determine whether we get the level of illumination from the landing lights to the level that it’s going to give early enough decision making in the event of an auto rotation at night. We’ll find out the extent to which we can illuminate landing areas in low light areas as well, for enhancing safety of VFR night flying.

JOIN OUR GROUP PRESENTATION

Are you interested in the HX50? Book your spot in our group presentation and learn why the HX50 will be better than your current helicopter.

What's in the presentation

Who

Mischa Gelb (aka Pilot Yellow) and Ruben Dias

What

Exclusive full details about the HX50 not yet available to the public

How

30 minutes presentation + Q&A

Be part of the journey

Get all the relevant news and updates about the HX50 delivered to your inbox.

HX50

Exterior Concept

Interior Concept

GT50 Turbine Engine

General Aviation 2.0

Hill Digital Cockpit

News & Stories

Technical Details

Range Simulator

Journey to HX50

ADDRESS

Hill Helicopters

Unit 3, Shackleton Way

Stafford, ST16 1GY

United Kingdom

Contact

General Enquiries:

+44 (0) 1384 590700

Accounts:

+44 (0) 1384 590700

Sales:

+44 (0) 1889 228040

hello@hillhelicopters.com

ADDRESS

Hill Helicopters

Unit 3, Shackleton Way

Stafford, ST16 1GY

United Kingdom

© 2026 HILL HELICOPTERS